When we decided to take a hands-on approach for this year's Drink Local issue, I knew the Inlander needed to do a collaboration beer with a local brewery.

I pitched the idea to Uprise Brewing Co. co-owner Ryan Hare. He was enthusiastic about the idea. It made sense. They were recently voted best new brewery by our readers, and they're our Kendall Yards neighbor.

The next week, I met with head brewer Riley Elmer. We discussed my idea further: I wanted to collaborate on a recipe, join them for the brew day and document the process — every step of the way. To top it off, I wanted to publish a homebrew-scaled recipe for interested readers.

Elmer was instantly on board.

TRY IT YOURSELF

Mosaic Montage hazy IPA will be on tap starting Friday, May 12. Join us for the official release from 4-7 pm.The Uprise Brewing Co. taproom is located at 617 N. Ash St. They're open Sun-Thur from 11 am-10 pm; Fri-Sat from 11 am-11 pm.

"I think it'd be a ton of fun for people to gain perspective of what it's like on the commercial brewing side of things," Elmer says at our initial meeting. "Then reward them with the beer to drink, and then also the homebrew recipe if they want to replicate it themselves."

The wheels are in motion. First, we need a style of beer. We talk about our love for lager beer, but there's a time constraint. We decide to make an IPA — shorter fermentation time and more accessible for anyone who would want to brew it at home.

If I'm reaching for an IPA, I personally gravitate toward hazy, juicy versions of the style. So that's the direction we head. I ask about hops. Elmer says they can get pretty much anything.

"Mosaic hops are my favorite by far," I respond. It's a versatile hop mostly used for aromatics. I dig the citrus and blueberry notes present in beers brewed with Mosaic.

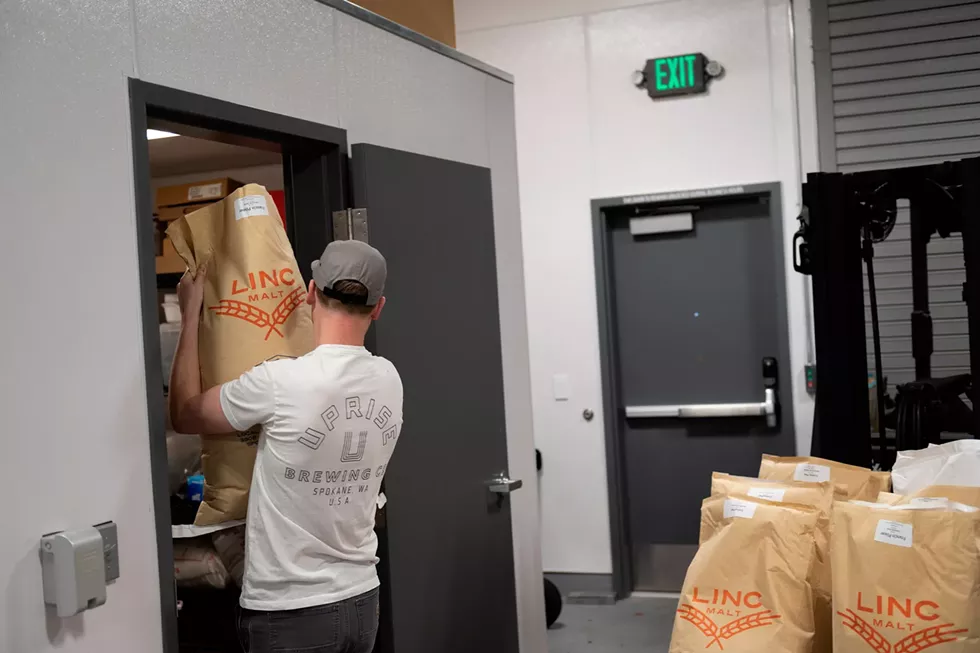

We then start going over other details needed for a recipe. I mention using LINC Malt for the grain. The malthouse located in Spokane Valley would bring another local element to the beer. It would also be a first for Uprise — their typical malt comes from Germany's Weyermann Malting Company. I leave it up to Elmer.

A few days later, we have a brew day locked in.

Elmer shares with me that he met with Brian Estes from LINC and decides to incorporate their grain into the recipe. Replacing nearly half their Pilsner malt base with LINC's Francin Pilsner, Elmer also wants to use LINC's Cashup Pale Wheat as an adjunct grain.

He lands on the idea of making a single-hopped hazy IPA, meaning Mosaic is the only hop used in the recipe. Another first for the brewery. To make it unique, he plans to use three different versions of the hop — T-90 pellets (the standard version of the hop), Cryo (double the potency of T-90 pellets) and Incognito (a newer, highly concentrated version of hops that's liquified).

Elmer decides to try out a new strain of yeast, Barbarian. It's also known as the Conan strain and was made popular for its use in New England IPAs, which is the model for our hazy IPAs on the West Coast.

The brew day hits and I arrive at Uprise at 7 am on a Thursday. I'm greeted by Elmer and assistant brewer Connor Kelly. The three of us — mostly them — get started.

BAG BY BAG, Riley Elmer dumps Pilsner, wheat and specialty malts into Uprise's small, yet powerful grain mill. The container siphons grain through its rollers to crush it to a specified size. A pump takes it up through the wall into the mash tun.

CONNOR KELLY MONITORS THE MASH TUN as hot water is added to the malt. We're trying to hit the target mash temperature of 156.9 degrees Fahrenheit. It sits for 15 minutes uninterrupted.

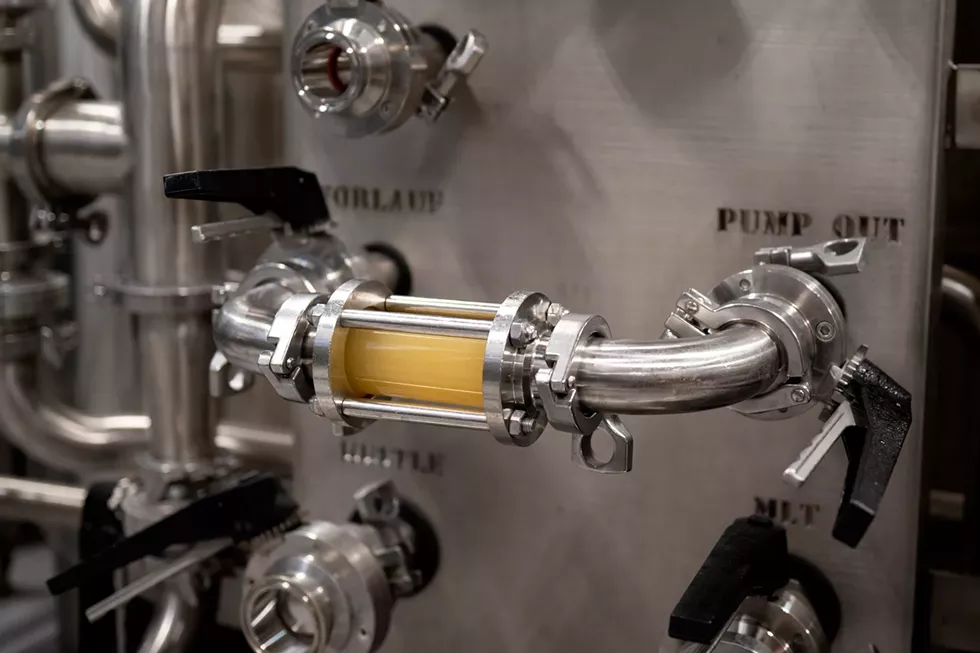

AT THIS STAGE, our liquid is now called wort. The hot water is saturated with the sugars from the malted grain. The next step is to Varlauf. This German technique recirculates the wort from the bottom back to the top of the grain bed, filtering out any unwanted grain residue. We do this until the wort is clear.

WE MOVE ON TO THE BOIL. The 13 barrels (or about 400 gallons) of wort is transferred from the mash tun to the kettle. The Uprise guys like to kick the kettle once it hits about five barrels of wort, which gets it to about boiling by the time it's filled. Once it's filled and boiling, the 65-minute boil begins.

A TEST IS DONE to check the pH level of the wort. At the 55-minute mark, minerals are added to further adjust the pH. This affects the body and mouthfeel of the potential beer.

THE HEAT TURNS OFF when the timer runs up. Five minutes later, the whirlpool phase begins. This is when the first addition of hops is added. After much back and forth, we decide to use about a quarter of the super-concentrated Incognito hops plus some of the classic T-90 hop pellets. The beer is transferred to a fermenter, its home for the next few weeks. Here, it's met with propagated yeast. It's now noon.

AN ORIGINAL GRAVITY (OG) READING is done using a hydrometer. This checks the sugars in the wort that will soon be transformed into alcohol thanks to the yeast. It's the first step of the calculation to determine the alcohol by volume (ABV) of the final beer. We successfully hit the target OG. We hit the target pH as well.

MONDAY ROLLS AROUND and the beer is ready to be dry-hopped. Before the additional hops, we taste the beer off the fermenter — it has a strong aroma of juicy fruits on the nose. This is where the bulk of our hops are added.

TO START THE PROCESS, I climb a ladder and open the tri-clamp valve at the top of the 10-barrel fermenter. I dump in the first 11-pound bag of Cryo Hops. Elmer adds the remaining bags of T-90 pellets. He seals it up and we wait.

IT'S NOW DAY 14. I show up at the brewery once again, this time to join Elmer and Kelly for another gravity reading and forced diacetyl testing. Diacetyl is a chemical that creates off-flavors such as buttered popcorn or butterscotch in beer. To start the process, Elmer pours some beer off the fermenter, seals it in a mason jar and sets it in a bath of 140-degree water. We leave it there for 15 minutes because diacetyl is more prevalent at higher temps. He then puts it in an ice bath to bring it back down to room temperature — we need to drink it.

ELMER POURS BOTH OF US a sample of the room temperature, flat beer. He also pours a fresh sample off the fermenter (this is our control). We taste them side-by-side to try to find any hints of buttered popcorn. We're in the clear.

THE BEER STILL ISN'T FINISHED. It's in a mostly dormant state, but is still fermenting. When it's done, it will be transferred to a brite tank where it will be chilled to serving temperature and further carbonated with additional carbon dioxide. From there, it will be packaged into kegs and ready to drink at Uprise's taproom. ♦

MORE MOSAIC

Five of our favorite local beers featuring Mosaic hops that you can find on tap right now.

GARLAND BREW WERKS

Pavilion Pale, 5% ABV

Brewed with Citra, Simcoe and Mosaic hops

HUMBLE ABODE BREWING

Dirty Sunshine New England IPA, 6.3% ABV

Hopped with Simcoe, El Dorado, Citra and Mosaic

LUMBERBEARD BREWING

So Easy Hazy Pale Ale, 5.5% ABV

Dry hopped with Mosaic, El Dorado, Simcoe and Citra hops

NO-LI BREWHOUSE

Cascade Fog Hazy IPA, 7.5% ABV

Hopped with Citra and Mosaic

YAYA BREWING COMPANY

Frugal Man Session IPA, 4.9% ABV

Packed with LINC Malt and exclusively hopped with Mosaic